Measuring & Analyzing Greenhouse Gases: Behind the Scenes

How are Secondary and Tertiary standards calibrated for CO2?

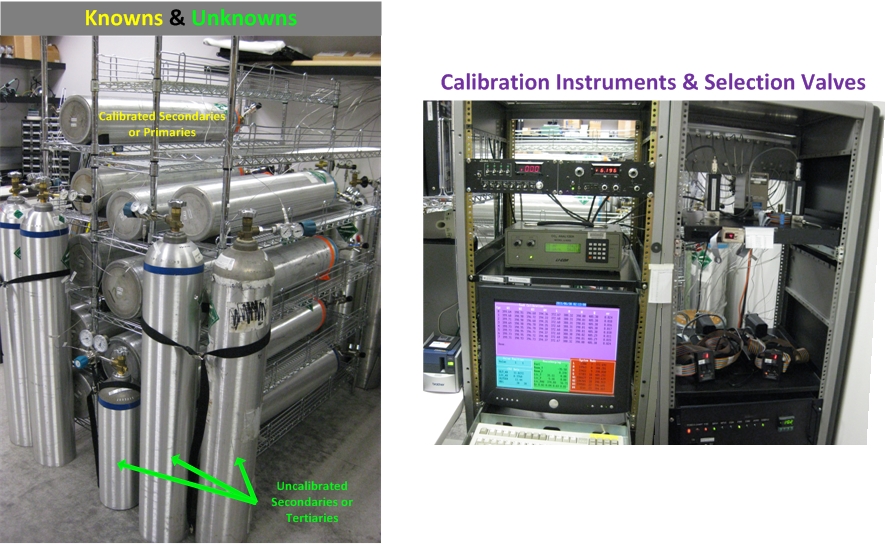

Secondary and Tertiary standards are calibrated by accurately measuring the CO2 concentration using a Non-Dispersive Infrared (NDIR) gas analyzer, which references CO2 concentrations from a known to an unknown using the fact that CO2 is a greenhouse gas and thus absorbs infrared radiation. In this case the knowns are the calibrated Primaries and Secondaries, which are used to calibrate the unknown Secondaries and Tertiaries.

The calibration system is very automated and can calibrate several air tanks at a time due to a network of selection valves and metal tubing connecting multiple air tanks to the CO2 analyzer. A computer program controls the calibration process, but the new air tanks and the correct standards have to first be connected to the calibration system by hand. The computer program is beneficial for keeping track of calibration results, which could get mixed up or contain errors if done by hand. The computer program also performs complicated mathematical calculations, something that would not be fun to do by hand!

-

Regulator Preparation

The first step in calibrating an air tank is to place a regulator on it. Placing a regulator onto a tank involves more than screwing it on, we need to take extra precautions to ensure there is no leftover air inside the regulator contaminating the new air being fed to the analyzer once the calibration process begins. This is done by flushing the regulator 5 times with air from inside the tank. On the 5th flushing, the air is left in the regulator overnight to allow the mixture of gases inside the tank to equilibrate on the inner walls of the regulator. Although this might seem overcautious, it prevents non-measurable problems later on.

The first step in calibrating an air tank is to place a regulator on it. Placing a regulator onto a tank involves more than screwing it on, we need to take extra precautions to ensure there is no leftover air inside the regulator contaminating the new air being fed to the analyzer once the calibration process begins. This is done by flushing the regulator 5 times with air from inside the tank. On the 5th flushing, the air is left in the regulator overnight to allow the mixture of gases inside the tank to equilibrate on the inner walls of the regulator. Although this might seem overcautious, it prevents non-measurable problems later on. -

Connecting to the Tubing Manifold

Metal tubing (the tubing manifold) is used to connect both the unknown air tanks and the standards to the stream selection valves that feed into the NDIR CO2 analyzer. Thin tubing is beneficial for our purposes because then there is less surface area within the tubing that needs to equilibrate to the new air from the uncalibrated air tanks. The photo on the left shows these sophisticated valves used to select which known and unknown tanks are sampled, which can each switch between 16 different inlets. One selection valve is for the known standards and the other is for the unknown air tanks being calibrated.

Metal tubing (the tubing manifold) is used to connect both the unknown air tanks and the standards to the stream selection valves that feed into the NDIR CO2 analyzer. Thin tubing is beneficial for our purposes because then there is less surface area within the tubing that needs to equilibrate to the new air from the uncalibrated air tanks. The photo on the left shows these sophisticated valves used to select which known and unknown tanks are sampled, which can each switch between 16 different inlets. One selection valve is for the known standards and the other is for the unknown air tanks being calibrated. -

Running the Calibration

The automated calibration process consists of 8 cycles. Each cycle is completed by measuring three or four known standards from lowest to highest CO2 concentration through the NDIR CO2 analyzer shown on the left, intermixed with one to five of the uncalibrated air tanks. Typically it takes a couple cycles to allow the air to equilibrate inside the tubing manifold, so the first couple cycles are thrown out and the last 6 cycles are used to get the true concentration of CO2.

The automated calibration process consists of 8 cycles. Each cycle is completed by measuring three or four known standards from lowest to highest CO2 concentration through the NDIR CO2 analyzer shown on the left, intermixed with one to five of the uncalibrated air tanks. Typically it takes a couple cycles to allow the air to equilibrate inside the tubing manifold, so the first couple cycles are thrown out and the last 6 cycles are used to get the true concentration of CO2.

To be extra certain that the CO2 concentration is accurate, this 8 cycle process is repeated two more times on separate days in between other calibrations. This measures the "repeatability" of our CO2 measurements, and they typically agree to within 0.02 ppm. Once the tanks are calibrated with their accurate CO2 concentration, they are considered "standards."

Which Standards Do We Use?

- If the uncalibrated air tank is to become a Secondary standard, then the Primary standards will be the known standards. If the uncalibrated air tank is to become a Tertiary standard, then Secondary standards will serve as the known standards.

- Deciding which Primary or Secondary standards to use as the knowns depends on a technique called bracketing. For example, if the targeted CO2 concentration of an uncalibrated air tank is 400 ppm, then known standards with CO2 concentrations close to 380 ppm, 390 ppm, 410 ppm, and 420 ppm (approximately 10 ppm apart in the "ambient rage" [The limits of what we may find in natural air]) will be used to calibrate the new air tank. This is bracketing, and it is done so that the response (how the analyzer's voltage reading relates to CO2 concentration) from the NDIR CO2 analyzer is well-defined within the range of CO2 concentrations that the uncalibrated air tank's targeted CO2 concentration lies.

Previous

Previous